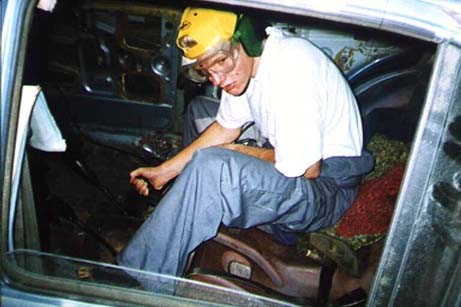

First I got one of my loyal subjects to cut the rust out of the passenger footwell and both rear footwells with an angle grinder.  Then we (Martyn & Hugh) had to wirebrush - with a powerdrill - around the holes above and below to remove the factory rustproofing, soundproofing and primer.  After successfully procrastinating for 3 months, I personally assisted in the welding in of replacement floor panels. The rear panels are 3mm thick for extra strength, as they are quite near the B-pillar floor seam. Great care was taken to ensure the strength of the welds. Many many thanks to Alan for the loan of his Mig welder and welding assistance (he's the only one in the photos because I can't take photos of myself (while welding) ).  An aluminium plate had been riveted over a hole caused by rust in the front quarter panel of the passenger side sill chassis rails. Upon removal of this plate I found that the chassis rail had been filled with a combination of bitumen-like rustproofer and engine oil. As removal of this was on the difficult side of impossible, and the metal we were welding served only to prevent water entering the chassis rail, we decided to weld with the bitumen in situ. Any good welder will tell you this leads to a weaker weld, who gives a fuck. The smoke you see Alan blowing on is coming from a rather substantial fire being fueled by the combination of bitumen-like rustproofer and engine oil which some dickhead had decided to weld over. Straight after taking this photo I jumped inside the car and helped Alan blow out the fire.  On the ground directly below the welding you can see drips of molten rustproofer. The welding on the plates is a little messy, however this will be covered by bitumen-like rust-proofer and eventually the front-left quarter panel.  This photo shows the plate in the passenger's footwell. It was fabricated out of 1mm mild steel for ease of shaping due to the multiple three-dimensional contours of the passenger's footwell. |

MORE INFORMATION TO BE ADDED PRECEDING AND FOLLOWING THE WELDING OF GERTRUDE'S FLOOR AT A LATER DATE. iF YOU HAVE ANY QUESTIONS, COMMENTS OR ENCOURAGEMENT ABOUT GERTY OR THIS PAGE, EMAIL ME AT

[email protected]